Specialists in Polymer Engineering

How can we help you?

The 3 Subsidiary companies of Clinipol Holdings Ltd.

Mowtec

Mowtec’s primary focuses are in the aerospace, maritime and printing sectors.

Aerospace

Supplying some of the leading OEM’s in the aerospace industry.

Maritime

Critical sealing solutions for over and under water systems.

Printing

Superior performance in both simple and complex printing systems.

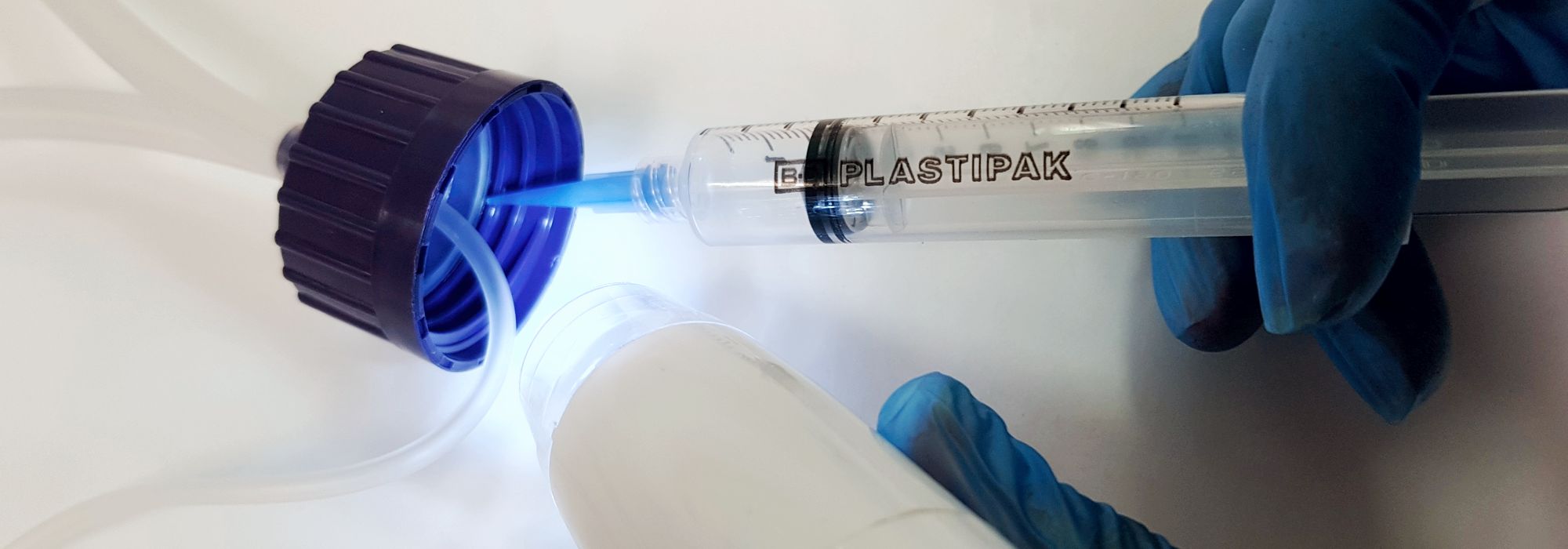

CPT – (Clinical Polymer Technologies)

Creating niche medical products within clean room environments.

Design and material selection assistance

Silicone Rubber Moulding

CPT has a quality system accredited to ISO 13485-2016; the present facilities on site make it possible for the company to produce niche products for several contamination free sectors.

The Complete Package

CPT is able to develop new, bespoke products, offering a complete turnkey solution for clients.

Medic

Medical device assembley.

Assembly

Complex assemblies of silicone and plastic components within ISO 8 Class K (100,000) cleanrooms. Specialist packaging in-house. Sterilisation assistance available.

Manufacturing Processes

Applications for the healthcare sector with firm diligence to stringent manufacturing procedures.

A Business In Parallel With Clients

Accelerated Production Turnaround

Reaching out to us is easy